Ceramic advantage---compared to metal bearings

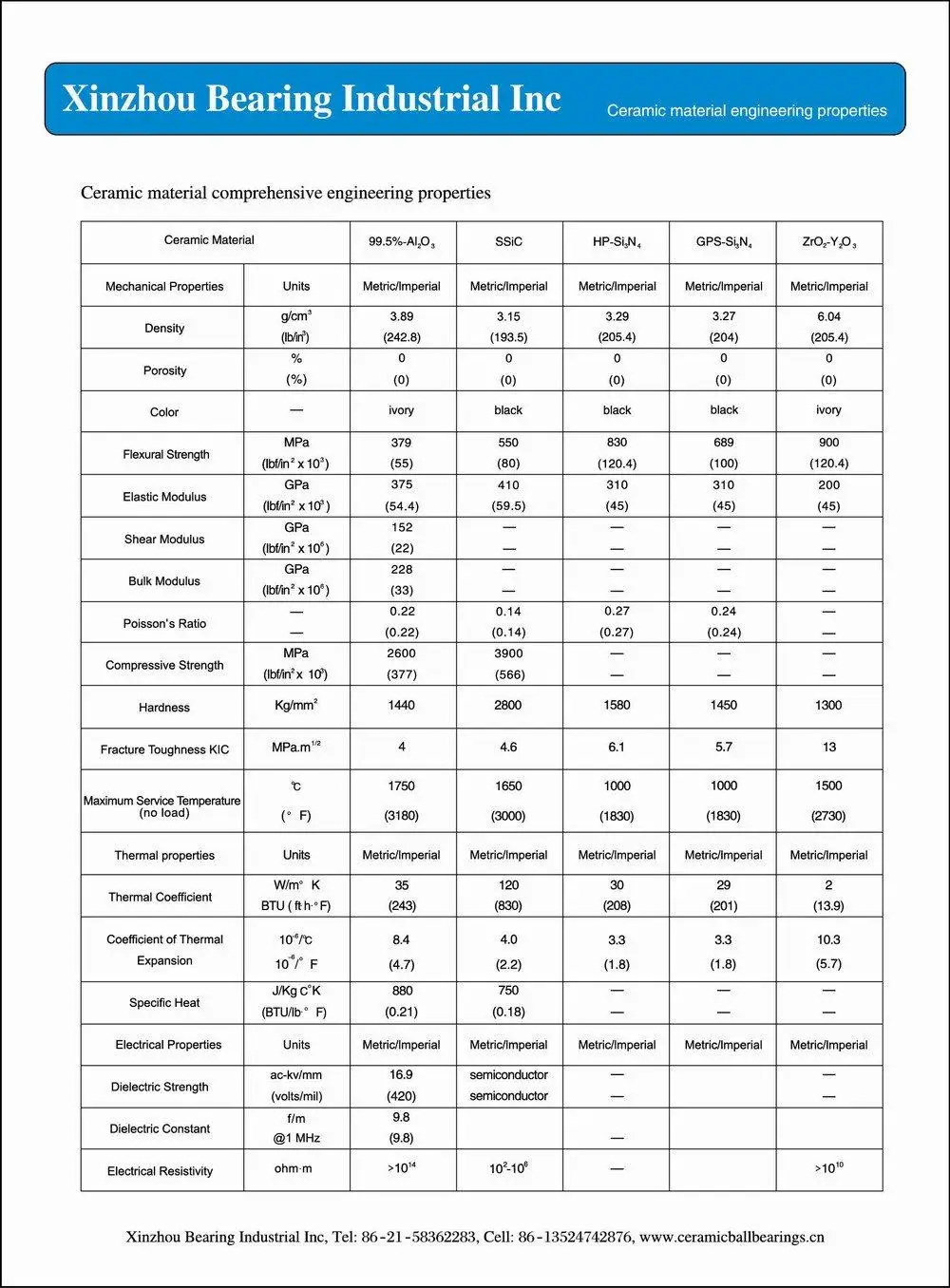

I) Higher limit speed: ceramic is lighter than steel, and can effectively restrain the centrifugal force, therefore enhancing the limit speed.

2) Higher precision usage: ceramic is harder and posses more elastic modulus than steel, which means ceramic bearing is stiffer, more rigid than steel bearing, thus can be used in higher precision condition.

3) Longer life: lighter ceramic requires less centrifugal force. thus extending bearing life, Furthermore the friction coefficient of ceramic is lower than steel, which also extends bearing life.

4) Higher temperature usage: ceramic is more mechanical stable at elevated temperature, thus could be used under higher temperature.

5) Temperature-variation usage: ceramic has a lower thermal expansion coefficient, thus the clearance and tolerance variation is lower than that of steel bearings; this leads to a large temperature-variation range for the usage of ceramic bearings.

6) Better seizure resistance; ceramic has a smaller thermal expansion coefficient, resulting in less thermal deformation, hence enhancing seizure resistance.

7) Could run without oil or grease: ceramic never rusts and is self-lubricated, thus can be used in situation that requires no oil or grease.

8) Resistant to acid, alkali and salt: chemical industry is the largest potential application industry where the ceramic bearing could be utilized.

9) More suitable for magnetic application: our ceramic bearing is non-magnetic. Which means it is difficult for magnetic patristic to adhere on the race, thus reducing particle-abrasion.

Ceramic ball bearings are vastly superior to metal bearings in the first three areas; while full ceramic bearings are superior in other areas.

Full silicon nitride bearing is superior to the full zirconia bearing; the bearing can endure higher temperatures and yields a higher resistant to acid, alkali and salt.

The

The